Nickel Plate

We provide a low stress satin nickel plated from a sulfamate nickel plating solution.

Nickel plating is a barrier layer which prevents the diffusion of copper into the gold top layer. If the copper is diffused into the gold the electrical characteristics (i.e. contact resistance), corrosion resistance of the contact will be degraded. The nickel layer also prevents the copper layer from physically deforming with repeated insertions of contacts.

Gold Plate

Gold plating has excellent electrical and thermal conductivity, it also offers exceptional solderability and is a superb reflector of infrared radiation. Alternate Finishing can provide two different types electrolytic gold plate and electroless gold. Each serves a different purpose;

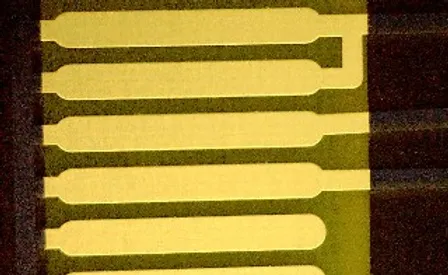

Hard Gold

Is used for contacts such as edge board connectors or a key pad. The hard gold we use is also a solderable gold.

The thickness specified for contacts is either .8 microns (30 microinches) minimum or 1.3 microns (50 microinches minimum). The thickness specified for solderability should be a maximum of .8 microns (30 microinches).

This gold meets the requirements of Mil-G-45204 and Mil-DTL-45204, type I or type II, grade C. It also meets the requirements ASTM B-488-01, type I or type II, code C.

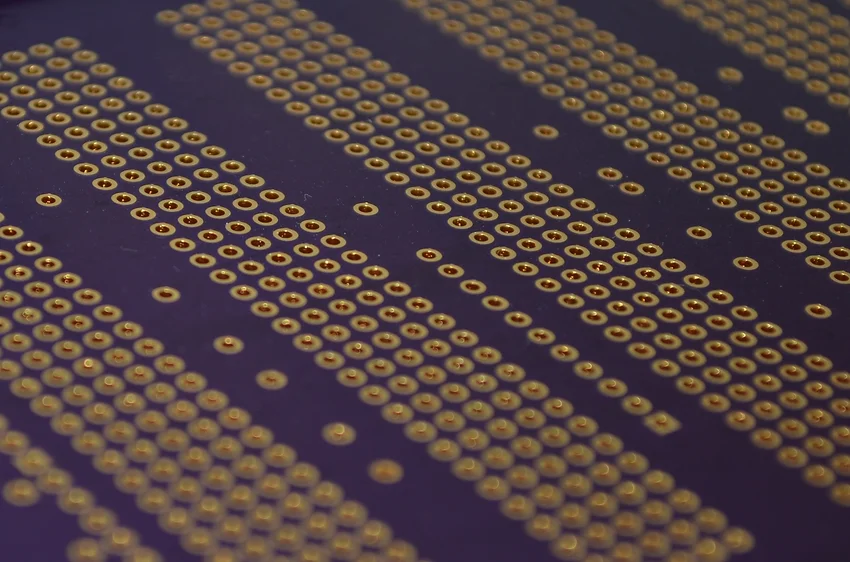

Soft Gold

This gold is specified when the assembly operations require wire bonding with gold wire. The purity and hardness of bondable soft gold must be closely monitored and controlled. The hardness must be 90 Knoop (25g load) or less. The purity must be 99.7% or greater to meet Type I requirements and 99.9% or greater to meet Type III requirements.

In the past, a relatively thick deposit was required when wire bonding with gold wire was going to be used. It was often specified at 100 microinches minimum. Advancements in wirebonding equipment and technique now allow bonding to be performed at a thickness as low as 0.3 microns (12 microinches), however most still specify 1.3 microns (50 microinches) minimum.This gold meets the requirements of Mil-G-45204 and Mil-DTL-45204, type III, grade A. It also meets the requirements of ASTM B-488-01, type III , Code A

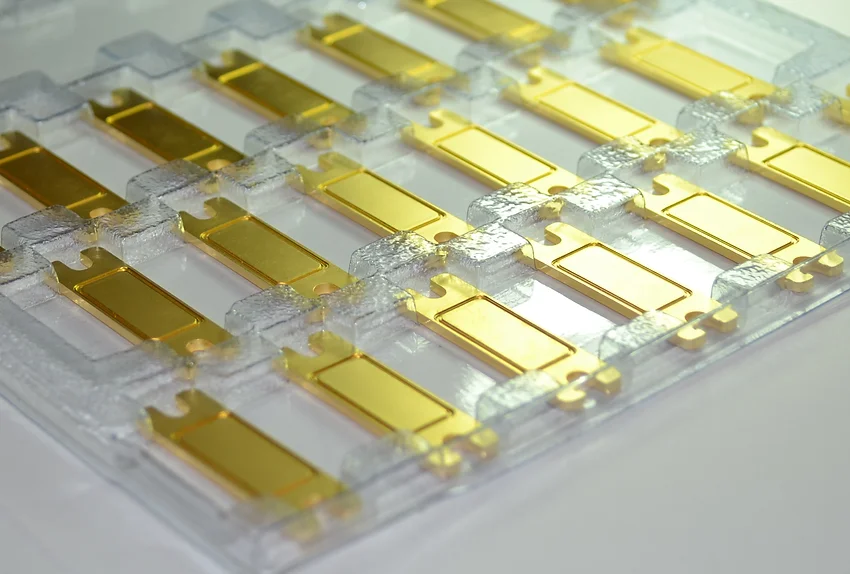

Electroless Gold

Using electroless gold plating, circuits can be etched and plated in their final configuration. This saves steps and allows the circuit design to take priority.

The gold deposited is wirebondable and solderable. It is essentialy identical to an electrolytic pure gold deposit according to Mil-DTL-45204 or ASTM B488 type III grade A regarding thickness, hardness and purity.

Electrolytic plating creates deposits that have thickness variations resulting primarily from the shape of the electrical field between the cathode surfaces and the anode. These deposits are thicker on corners and edges and surfaces where the distance to the anode is shortest. They are also thinner in the middle of surfaces, inside of holes and on surfaces facing away from the anode.

Electroless plating completely eliminates this source of variation. Electroless gold plated deposits are uniform in thickness around corners, on both sides of a part, even on the inside walls of small holes that may be very deep.