About ENIG

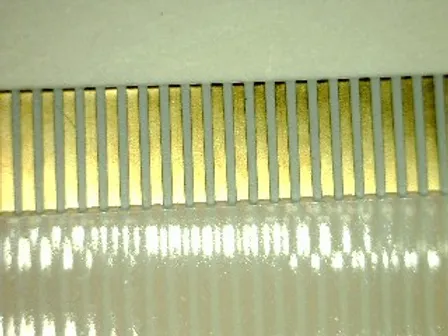

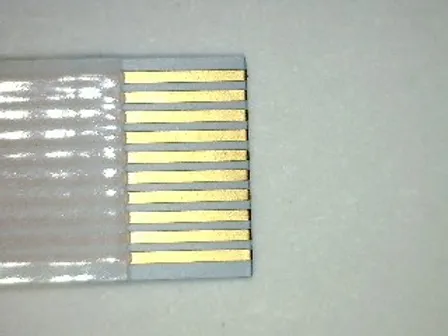

Electroless Nickel and Immersion Gold has a flat solderable surface and allows tighter placement of surface mount pads. The finish is solderable and bondable with aluminum wire.

The process line is fully automated with vibration in all process stations to assure bubbles are removed from the holes.

Electroless Nickel (EN Plating) is applied after copper trace/feature definition (after Cu plate, image, and etch operations). It can be applied before or after the soldermask application providing a conformal coating on all exposed copper surfaces including sidewalls.

The deposit is a nominal 120 – 240 micro-inches of approximately 93% purity nickel over exposed copper traces and features. Intrinsic to the electroless process is a significant amount of phosphorous that is co-deposited with the nickel. We also have two electroless nickel choices one 6-8% phosphorous and another with 8-10% phosphorous.

The electroless nickel acts as a barrier layer between the copper and the gold, preventing unwanted (unsolderable) intermetallic formation. The electroless nickel layer also adds strength to plated through holes and vias.

Immersion Gold is applied after the electroless nickel process and provides a gold coating on all exposed nickel surfaces including sidewalls.

Gold is applied by a molecular replacement process in which previously deposited nickel molecules are replaced by gold molecules in a processing tank. The gold deposited is 99.99% pure, and its thickness is allowed to build up to 2 to 5 micro-inches. By design, the immersion deposition process is self-limiting. When the underlying nickel is completely covered the reaction will stop and no more gold will deposit. Immersion gold provides excellent solderability properties, and it retards passivation (oxidation) of the nickel layer.

The combined nickel/gold, ENIG, metallization provides excellent corrosion resistance, solderabilty, pad coplanarity, and shelf life. It is a good choice for fine-pitch SMT and BGA technologies.

General Information

Size limits – The size most often received is 24″ x18″ but panels can be any size up to 26″ x 30″.

Alternate Finishing (AFI) can plate the whole panel after you etch it. No tin or tin-lead may be exposed anywhere on the panel including edges and inside holes. We recommend that you run the panels through the solder strip with some extra time to ensure all the intermettalic layer is removed and that you bake the panels at 250 deg F for one hour.

AFI can plate the pads only. This is done after you apply the solder mask on the bare copper. If holes are plugged they need to be completely plugged flush. Holes that are partially filled with solder mask or plugged from one side cause incomplete catalysation and some pads may not plate correctly.

We plate panels that have many different brands of solder mask and do not recommend any particular brand or model. However, please follow closely any recommendations that your mask supplier has regarding preparing panels for electroless nickel and immersion gold plating.

It is very important that the tin or tin-lead used for etch resist is completely removed prior to soldermask application.

Avoid tight registration of the solder mask. If possible open a window around rows of fine pitched features.

Solder mask must be fully cured, however, take care not to over cure it.

Boards must stabilize after processing. Panels that fail soldermask adhesion tests after processing will likely pass in as little as a few hours or the next day. For this reason we only tape test on waste areas of the panel for plating adhesion tests.