Important Takeaways

- Material quality matters: High-Tg and low-CTE laminates ensure reliability under thermal stress.

- Design is ruggedized: Layouts account for shock, vibration, EMI, and power distribution.

- Manufacturing is precise: Tight tolerances, impedance control, and full traceability are required.

- Testing is extensive: Electrical, environmental, visual, and non-destructive methods confirm durability.

- Finishes must endure: ENIG and other flat, corrosion-resistant finishes support solderability.

- Documentation ensures accountability: Every material and process is tracked, often under ITAR rules.

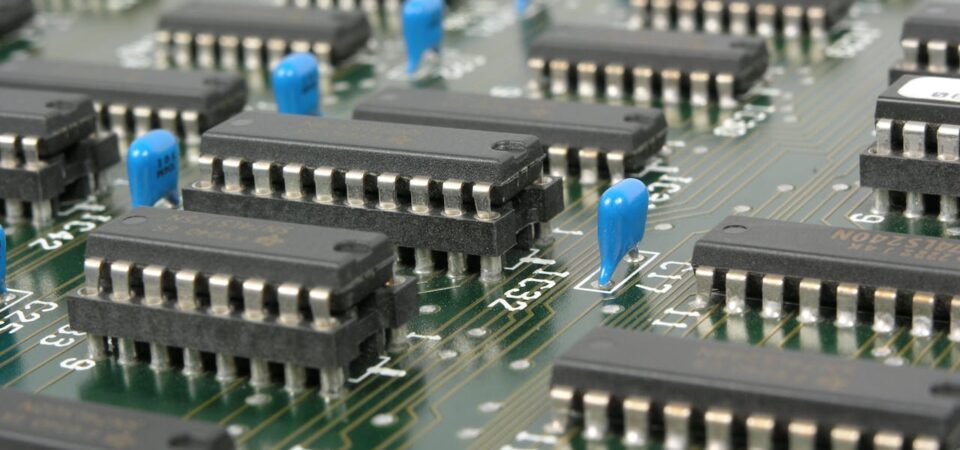

When you hear the phrase mil-spec PCB, it usually signals something built to a higher level of toughness. These aren’t the boards inside a consumer gadget that can be swapped out if they fail. They are found in defense, satellites, and, basically, places where downtime is not only inconvenient but also dangerous.

This is why MIL standards for PCB design exist: to make sure that all boards used in these applications can handle shock, vibration, temperature swings, and long service life without cutting corners.

Let’s now explore the characteristics of these boards and what makes them high-quality.

Robust Material Selection

A strong board starts with strong materials. That might sound obvious, but the difference between ordinary substrates and those chosen for a mil-spec PCB is night and day.

High-Tg laminates are often used because they can withstand extreme heat before softening. In other words, they don’t collapse when exposed to thermal stress over and over again.

Another big factor is the Coefficient of Thermal Expansion (CTE). If materials expand and contract too much, connections between copper and laminate start to fail. Cracks and delamination problems follow, reducing the reliability of the material.

Military-grade boards avoid this by sticking to low-CTE materials that remain stable even under fast shifts in temperature.

It’s not even just good engineering practice. It’s also about compliance. Mil-spec PCB standards outline which materials meet the requirements.

Rugged Design and Layout

Even the best materials can’t save a poor layout. Designers who work on these PCBs spend a lot of time thinking about real-world stress: shock from impact, vibration from engines, and even electromagnetic noise.

When it comes to MIL standards for PCB design, the boards must be rugged enough to hold up inside a fighter jet, for example, or a naval vessel.

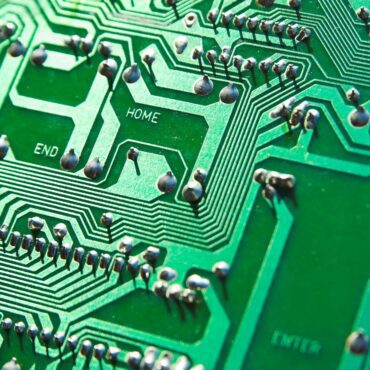

Rules around electromagnetic interference (EMI) and electromagnetic compatibility (EMC) also shape the layout early on. To keep the signals in mil-spec PCBs clean, trace spacing and grounding strategies are used to meet that goal.

Power distribution is another concern. If the current isn’t balanced correctly, performance across the system takes a hit.

To add protection, many boards are coated with a thin conformal layer. That film keeps out moisture, dust, and corrosion, which are hard things to avoid in real deployments.

Strict Manufacturing Processes

Producing these PCBs also comes with detailed process controls because good design doesn’t matter if the manufacturing falls short.

So, impedance requirements must be locked down because even slight variations can distort high-speed signals, which is unacceptable in mil-spec PCBs.

Even drill holes, plating, and copper thickness are all held to tighter tolerances than what you’d see in commercial products.

Traceability also plays a big role. Every material batch and every process step is documented. If something goes wrong later, teams can trace it back to a specific lot or procedure.

Shops that handle defense work have AS9100 certification. This certification requires strict quality management. They have to consistently meet the high MIL standards for PCB design, not just one-off successes.

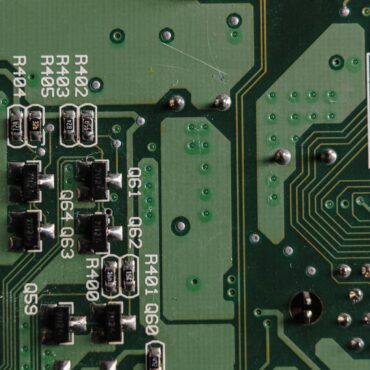

Comprehensive Testing and Inspection

Testing is where theory meets reality. A mil-spec PCB has to prove that it can perform reliably under pressure. That starts with electrical tests to check continuity and isolation, but it doesn’t end there.

Environmental testing is also done to expose the boards to temperature cycling, humidity, vibration, and other conditions to simulate real-life conditions.

Inspectors are equally unforgiving. IPC-A-600 Class 3 visual standards leave little room for defects. What might pass in consumer electronics won’t pass here.

There are many non-destructive tests done on mil-spec PCBs to catch hidden issues. For instance, inspectors will normally use X-rays to see inside the board layers without damaging them.

Of course, not every shop runs all these tests, but somewhere in the production chain, each board must pass these hurdles to earn the military designation.

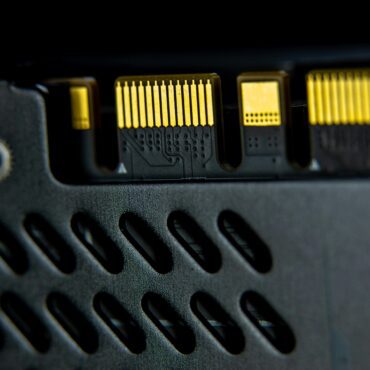

Reliable Surface Finishes

The surface finish can seem like a small detail, but it affects both solderability and long-term durability of PCBs.

One of the most common finishing choices for mil-spec PCBs is Electroless Nickel Immersion Gold, or ENIG. This is because ENIG provides a flat surface and strong corrosion resistance, which creates reliable solder joints needed in Mil standards for PCB design.

It’s especially valuable with fine-pitch components.

Other options include immersion silver and immersion tin. What you won’t see in this environment is HASL, since it doesn’t provide the flatness or reliability needed for critical work. The finish has to survive extreme conditions just like the rest of the board.

Documentation and Traceability

Another thing that sets a mil spec PCB apart from the rest is how it’s documented. Everything from components to processes is documented, but that paperwork is not for nothing. It keeps everyone involved, accountable, and compliant.

If a capacitor fails, teams can trace it back to a batch number and supplier. If a plating process introduces a flaw, records show exactly when and how it was done.

Having a clear trail of documentation proves the board was built and handled according to strict standards.

Conclusion

For manufacturers who need mil-spec PCB plating work that supports these requirements, Alternate Finishing, Inc. offers several plating services, including ENIG plating.

Backed by our reputation for reliability and ITAR-registered metal finishing services, our processes align with the same expectations that guide defense and aerospace projects. Call us today for a quote.

Robert Peterson is President of Alternate Finishing, an AS9100D, ISO 9001:2015, and ITAR registered metal finishing provider serving customers across the USA and Canada. With more than four decades of experience in printed circuit boards and metal finishing, Robert is certified by the National Association of Metal Finishers as an electronic specialist. He’s also an avid photographer.