Key Takeaways:

- ENIG (Electroless Nickel Immersion Gold) offers superior solderability, flatness, and corrosion resistance for high-reliability PCBs.

- HASL (Hot Air Solder Leveling) is a cost-effective PCB finish with good solderability, but uneven surface.

- ENIG’s superior flatness suits fine-pitch components; HASL is better for larger components and cost-driven applications.

- ENIG provides excellent corrosion resistance; HASL’s varies, with lead-free being more susceptible to oxidation.

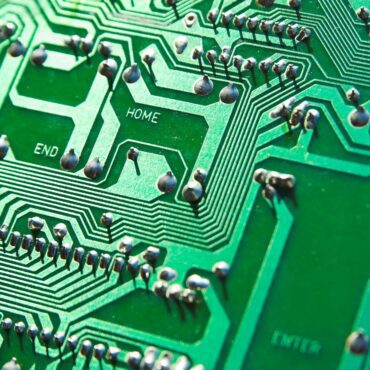

Surface finishes in PCBs affect not only the functionality but also the longevity and solderability of the board. Two of the most common finishes are ENIG and HASL which is why we must do an ENIG vs. HASL comparison.

Each of these finishes has its unique properties, advantages, and disadvantages. Even their applications can vary since they are both best suited for different conditions for optimal performance of the final product.

In this article, we will compare both finishes in detail to gain a better understanding of what they are as well as their benefits and limitations so that we can know when to apply each of them for optimal product performance.

First, we’ll explore a brief overview of both finishes to learn what each of them is.

ENIG vs. HASL: An Introduction

What Is ENIG?

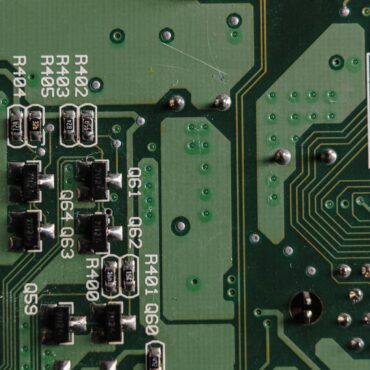

ENIG stands for Electroless Nickel Immersion Gold, a surface finish that applies a layer of electroless nickel beneath a thin layer of immersion gold. The nickel layer acts as a barrier and provides structural support to the surface pads, while the thin gold layer protects the nickel from oxidation and ensures good solderability.

The ENIG process involves two primary steps:

- Electroless Nickel Deposition: A chemical reaction deposits a uniform nickel layer on the copper pads.

- Immersion Gold Plating: A very thin layer of gold is deposited on top of the nickel via an immersion process.

In an ENIG vs. HASL comparison, the fundamental difference between the two lies in their approaches, processes, and materials used. ENIG finishes must also conform to IPC-4552 standards. Now let us briefly discuss HASL.

What is HASL?

HASL stands for Hot Air Solder Leveling. This process involves dipping the PCB into a molten tin-lead or lead-free solder bath, followed by using hot air to remove excess solder from the surface. This creates a solderable surface over the copper pads. HASL is also one of the oldest and most cost-effective surface finishes available for PCBs.

HASL has two variations:

- Lead-based HASL which uses a tin-lead solder.

- Lead-Free HASL: This one complies with RoHS regulations and uses lead-free alloys like tin-copper or tin-silver-copper.

HASL finishes generally follow IPC-6012 and IPC-A-610 standards for quality and inspection.

ENIG vs. HASL: Key Factors To Compare

Solderability

ENIG offers excellent solderability with a smooth surface and gold layer that protects against oxidation.

HASL also provides good solderability, but performance depends on solder layer consistency. Leaded HASL is generally easier to solder than lead-free, though the latter is more eco-friendly despite higher reflow temperatures.

Surface Flatness (Planarity)

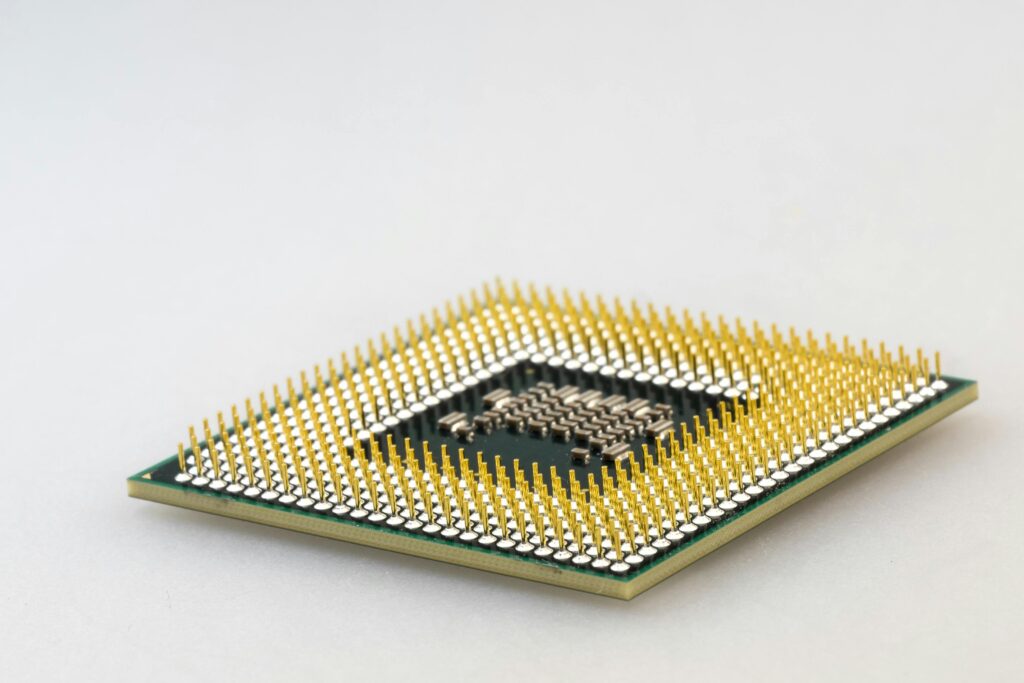

In the ENIG vs. HASL comparison, ENIG’s key advantage is its superior planarity, making it ideal for fine-pitch components like Ball Grid Arrays and Surface Mount Technology.

HASL, with its uneven surface, is less suited for high-density boards and precise component placement, though it’s acceptable for larger components.

Corrosion Resistance

In PCB finishes, the gold layer in ENIG provides excellent corrosion resistance that protects the nickel from oxidation. This makes ENIG a preferred choice for applications that require high reliability and long-term durability like military electronics and medical devices.

HASL finishes offer moderate corrosion resistance due to the protective properties of the tin-lead alloy. However, lead-free HASL is more susceptible to oxidation and corrosion, especially in harsh environments.

ENIG vs. HASL in Thermal Cycling and Mechanical Stress

ENIG offers good thermal cycling stability. Modern chemistries have almost entirely eliminated nickel corrosion and associated potential issues.

HASL, particularly leaded versions, is resilient to thermal cycling due to its thick solder layer, though lead-free HASL can be more brittle and prone to cracking during reflow.

Cost

This is one of the biggest reasons people stick with HASL. It’s simple, cheap, and fast. ENIG, on the other hand, costs more: not just because of the gold, but also due to tighter process controls.

That said, in ENIG vs. HASL, if you’re building a board where failure is costly, ENIG often pays for itself by reducing issues down the line.

Environmental Considerations

ENIG is lead-free and typically compliant with RoHS out of the box. Newer processes are also phasing out older, more hazardous chemicals.

With HASL, you need to be more careful. The leaded version obviously doesn’t pass RoHS, and even lead-free HASL still relies on higher temps and fluxes that aren’t ideal for every operation.

Sector Specific Preferences

ENIG is the finish of choice for high-reliability applications like military PCB finishes, particularly where fine-pitch components or high-density interconnections are used. It is commonly found in sectors like aerospace, automotive, telecommunications, and medical devices.

In the ENIG vs. HASL comparison, HASL is widely used in PCBs for consumer electronics, industrial equipment, and applications where cost is a primary concern. It is well-suited for through-hole components and less sensitive designs but is less ideal for modern high-density interconnect (HDI) PCB finishes.

ENIG and HASL Services at Alternate Finishing, Inc.

At Alternate Finishing, Inc., we offer reliable ENIG plating services,, and other metal plating services for customers across the USA and Canada and if you still need to learn more about ENIG vs. HASL, we can help guide you. Since we are ITAR registered, we invite you to explore our ITAR-registered metal finishing services. We have quick turnarounds on jobs, therefore, if you need quick and reliable ENIG or HASL services, we are here to help. Call us for a quote.

Frequently Asked Questions

What IPC standard governs ENIG plating?

ENIG is covered by IPC-4552 which defines minimum nickel and gold thicknesses, purity, and test criteria for solderability.

Is HASL compliant with RoHS?

Only lead-free HASL is RoHS-compliant. Traditional HASL uses leaded solder and is not suitable for RoHS-restricted products.

ENIG vs. HASL: Which finish is better for fine-pitch or BGA components?

ENIG is the better choice due to its flat surface. HASL’s uneven coating can interfere if you’re trying to place the components precisely.

What is the typical shelf life of each finish?

ENIG can maintain solderability for 12 months or more. HASL generally lasts 6 to 12 months, but lead-free variants may oxidize faster.

How do ENIG and HASL finishes affect rework or repairs?

ENIG’s stability makes it easier to rework without oxidation. HASL can be reworked easily too, but repeated heat exposure may degrade the finish over time.

Robert Peterson is President of Alternate Finishing, an AS9100D, ISO 9001:2015, and ITAR registered metal finishing provider serving customers across the USA and Canada. With more than four decades of experience in printed circuit boards and metal finishing, Robert is certified by the National Association of Metal Finishers as an electronic specialist. He’s also an avid photographer.