Gold Plating for Quality PCB Finishes

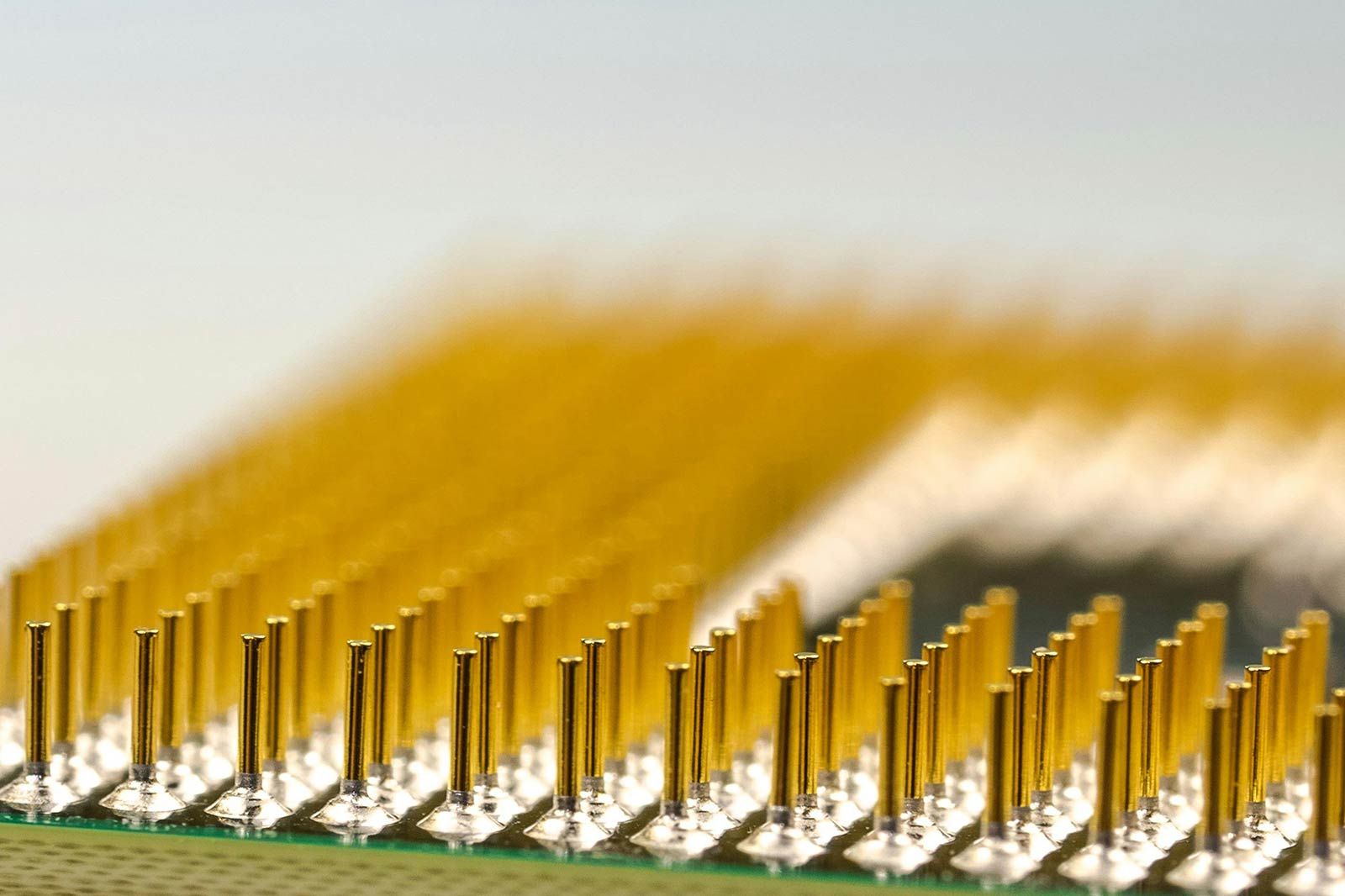

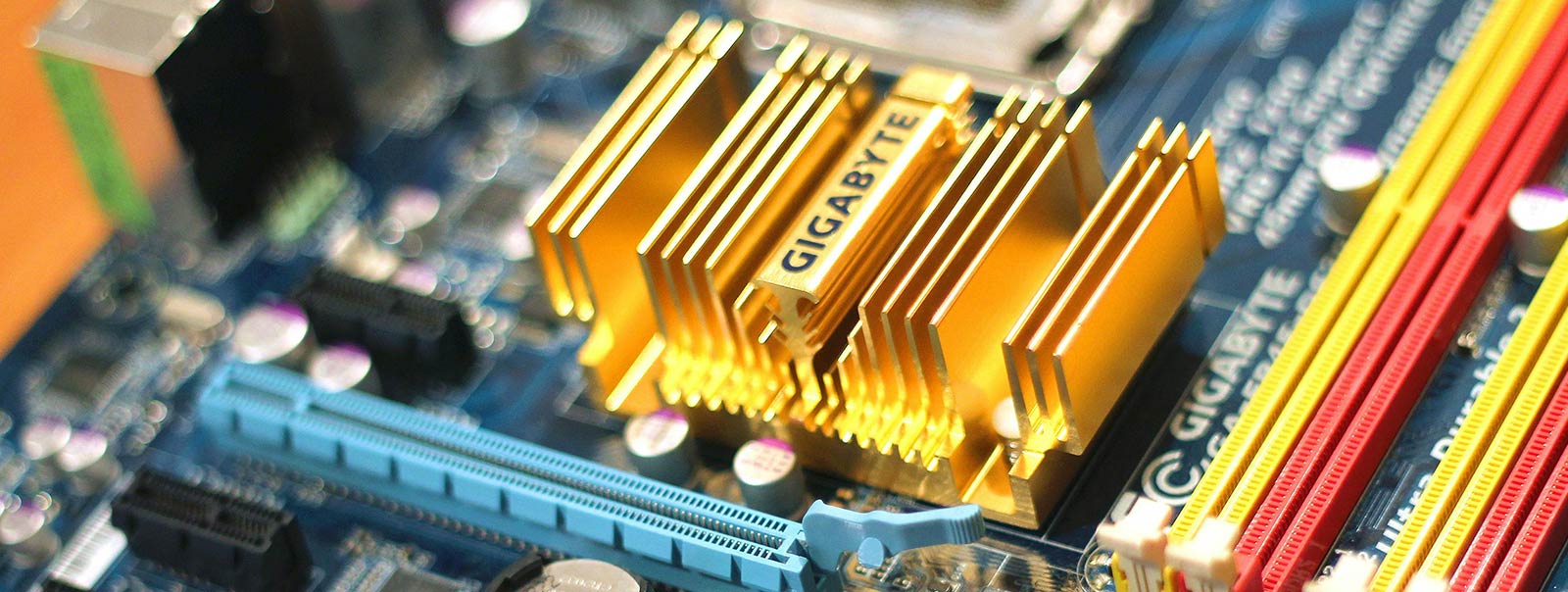

Gold is prized for its exceptional conductivity, resistance to oxidation, durability, and aesthetics under harsh environmental conditions. Gold plating PCBs gives them better performance and longevity, especially in high-reliability sectors like aerospace, defense, and medical electronics. At Alternate Finishing, Inc., we offer hard gold (Type II, Code C) for contact and wear resistance, and soft gold (Type III code A) for applications requiring wire bonding, excellent solderability, and low contact resistance.

In addition to standalone gold plating, we also offer specialized gold plating services such as ENIG (Electroless Nickel and Immersion Gold) and Reduction-Assisted Immersion Gold (RAIG). Both of these processes provide highly uniform, solderable surfaces and are ideal for surface mount technology and BGA components.

Request a Quote

Our Plating Procеss

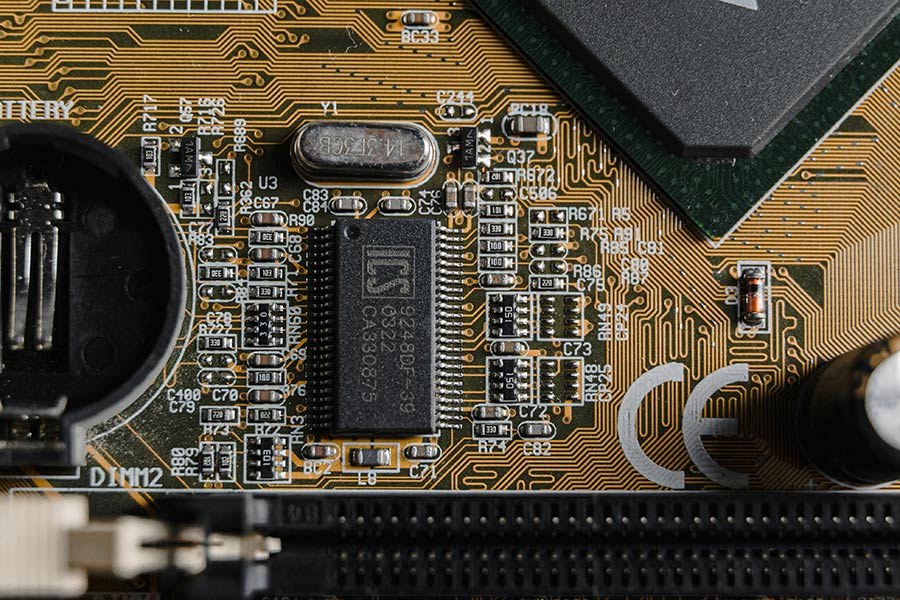

At AFI, our gold plating process for PCBs is a highly controlled, multi-step procedure that starts with rigorous surface preparation to eliminate oxides and other contaminants. Since we offer both electrolytic and immersion gold plating, we will briefly discuss each of them now.

Electrolytic gold plating uses an electric current to deposit dense layers of gold. It is ideal for connectors and high-wear areas.

Immersion plating is a chemical process that provides uniform, solder-friendly finishes, which is why our immersion gold plating services – particularly ENIG and RAIG processes – are commonly used by PCB producers.

Work With Us

Located in the Metro Boston area, Alternate Finishing, Inc. provides precision plating services for clients across the USA and Canada and our turnarounds on jobs are fast.

For reliable and high-quality gold plating services, contact us. Our team is ready to provide you with a customized solution that meets your specific needs. Call for a Quote.

Frequently Asked Questions

What is the typical thickness of gold plating applied at Alternate Finishing, Inc.?

AFI applies gold plating in thicknesses ranging from 1 to 350 microinches, depending on the application. Soft gold finishes for wire bonding or soldering usually range from 1–20 µin. Some types of wire bonding require thicker gold. We have had customers ask for up to 350 microinches. Hard gold finishes for edge connectors may require a minimum of 50 µin. All plating is performed to meet MIL-DTL-45204 and ASTM B488 standards.

What is the difference between hard gold and soft gold plating?

Soft gold contains 99.9% pure gold, while hard gold is alloyed with small amounts of cobalt or nickel. We use each for different applications in our gold-plating services.

What are the advantages of gold plating for PCBs?

Gold plating offers excellent corrosion resistance, high electrical conductivity, and consistent solderability.