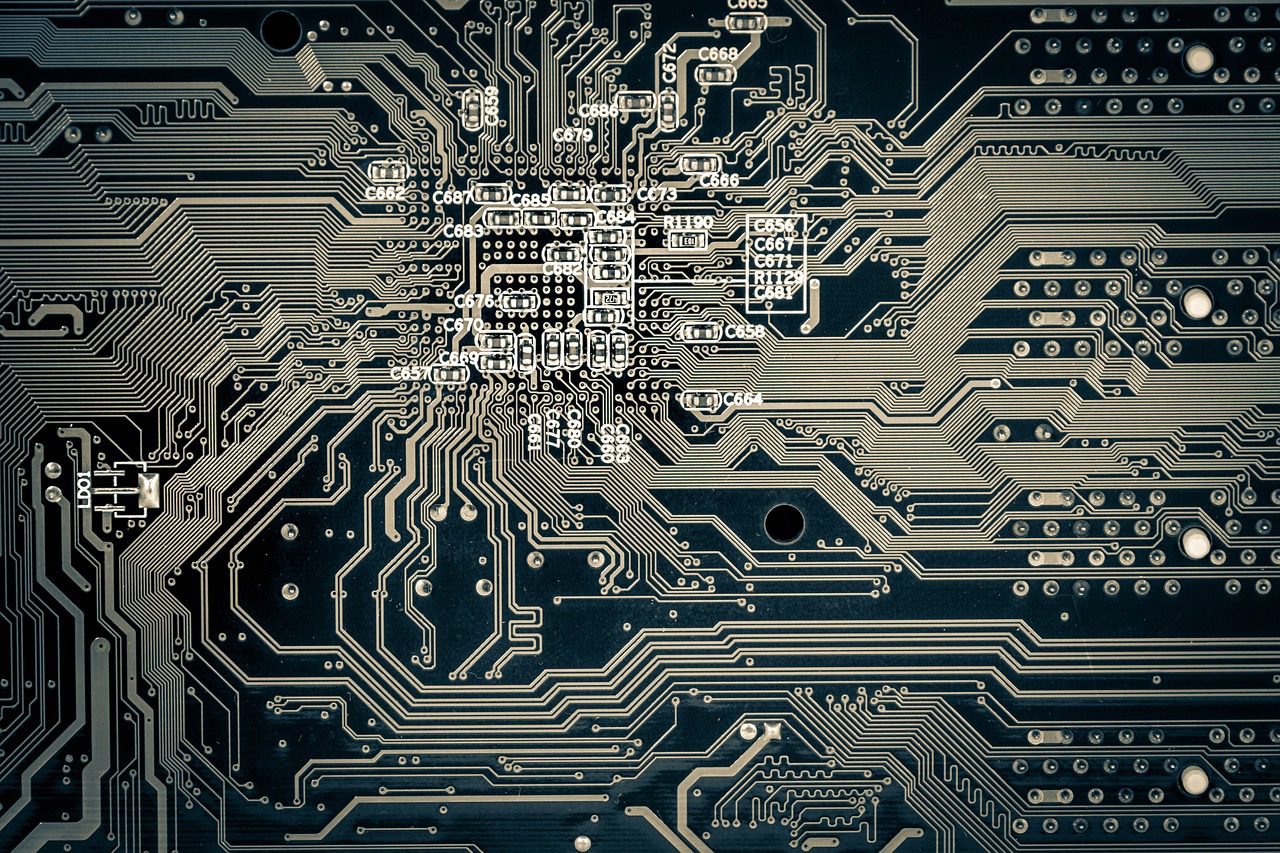

Gold-plated nickel plays an important role in enhancing several crucial properties of electronic components. The nickel acts as a barrier layer, preventing copper from diffusing into the gold and this is great for ensuring long-term stability, gold also provides excellent electrical conductivity and more.

This combination of metals creates many benefits as well as challenges. Understanding what these are helps us select the right surface finish for a given application, ensuring optimal performance and reliability. Nickel and gold plating are discussed in more detail below, including advantages and disadvantages.

Nickel Plate

We provide a low-stress satin nickel plated from a sulfamate nickel plating solution.

For nickel and gold plating, nickel plating is a barrier layer that prevents the diffusion of copper into the gold top layer. If the copper is diffused into the gold the electrical characteristics (i.e. contact resistance), and corrosion resistance of the contact will be degraded. The nickel layer also prevents the copper layer from physically deforming with repeated insertions of contacts.

Nickel plating meets the requirements of QQ-N-290, ASTM B689, AMS 2403, AMS 2424, and MIL-P-27418 specifications.

Request a Quote

Gold Plate

Gold plating has exceptional properties such as great electrical and thermal conductivity, superb solderability, and excellent reflectivity of infrared radiation. The gold plating services at Alternate Finishing use two different approaches: An electrolytic gold plate and an electroless gold. Each serves a different purpose.

Hard Gold

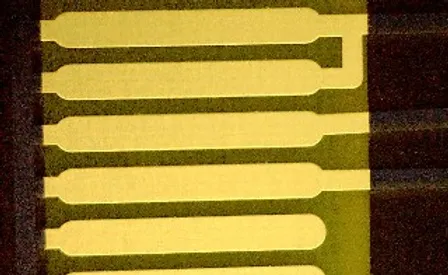

In nickel and gold plating, hard gold is used for contacts such as edge board connectors or a keypad on a gold-plated nickel PCB board. The hard gold we use is also a solderable gold.

The contact thickness is either .8 microns (30 microinches) minimum or 1.3 microns (50 microinches minimum). The thickness specified for solderability should be a maximum of .8 microns (30 microinches).

This gold meets the requirements of Mil-G-45204 and Mil-DTL-45204, type I or type II, grade C. It also meets the requirements of ASTM B-488-01, type I or type II, code C.

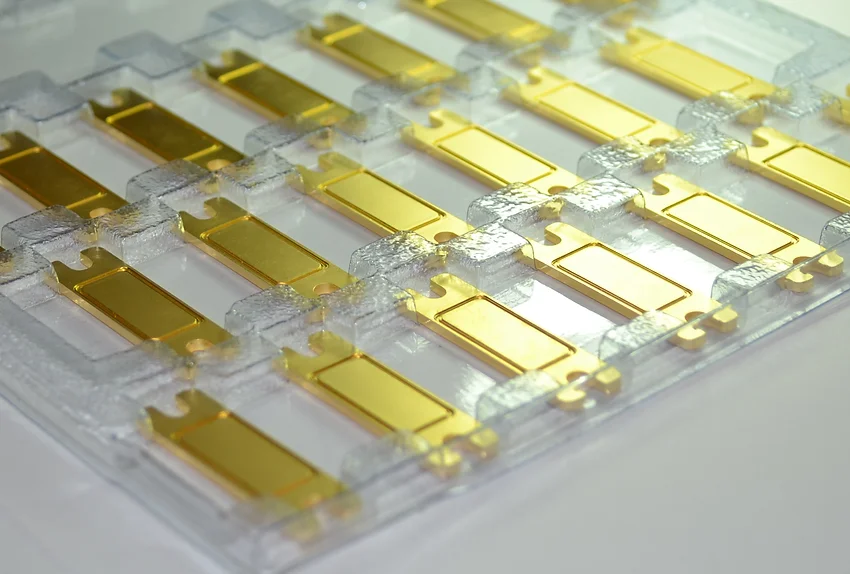

Soft Gold

This gold is specified when the assembly operations require wire bonding with gold wire. The purity and hardness of bondable soft gold must be closely monitored and controlled. To meet the desired specifications, the hardness of the plating should not exceed 90 Knoop (25g load). The purity must be 99.7% or greater to meet Type I requirements and 99.9% or greater to meet Type III requirements.

In the past, the soft gold plating service required a relatively thick deposit when wire bonding with gold wire was going to be used. It was often specified at 100 microinches minimum.

Advancements in wire bonding equipment and technique now allow bonding to be performed at a thickness as low as 0.3 microns (12 microinches), however, most still specify 1.3 microns (50 microinches) minimum, although it’s important to note that the thickness for nickel and gold plating can vary depending on the application and industry standards. This gold meets the requirements of Mil-G-45204 and Mil-DTL-45204, type III, grade A. It also meets the requirements of ASTM B-488-01, type III, Code A.

Electroless Gold

With our electroless gold plating service, circuits can be etched and plated in their final configuration. This saves steps and allows the circuit design to take priority.

The gold deposited is wire-bondable and solderable. It is essentially identical to an electrolytic pure gold deposit according to Mil-DTL-45204 or ASTM B488 type III grade A regarding thickness, hardness, and purity.

Electrolytic plating results in deposits with thickness discrepancies primarily influenced by the shape of the electric field between the cathode and anode surfaces.

These variations manifest as thicker deposits on corners, edges, and surfaces closer to the anode, while thinner layers are observed on flat surfaces, inside holes, and areas facing away from the anode.

In contrast, electroless nickel and gold plating eliminates this issue. It ensures uniform thickness of gold-plated deposits, regardless of corners, sides, or internal structures such as deep holes.

Pros And Cons of Nickel and Gold Plating

| Advantages | Disadvantages |

|---|---|

| Corrosion Resistance: Nickel forms a protective barrier that prevents oxidation, while gold resists tarnish and further protects against environmental factors. | Cost: Gold is expensive, which increases the overall cost of the plating process. |

| Solderability: Gold’s highly conductive and oxidation-resistant surface provides excellent solderability, especially in fine-pitch components. | Brittleness: Nickel layers in gold-plated nickel can introduce brittleness, especially in thicker coatings, affecting mechanical properties. |

| Durability: Nickel’s hardness contributes to wear resistance, providing a robust and long-lasting surface. | Thickness Control: Precise control of gold thickness is critical to ensure solderability without excessive costs. |

| Electrical Conductivity: Gold offers outstanding electrical conductivity, making it ideal for high-frequency and low-resistance applications. | Environmental Concerns: The processes involved in nickel and gold plating may raise environmental and health concerns due to the chemicals used. |

| Prevention of Copper Diffusion: Nickel acts as a diffusion barrier, preventing copper from migrating into the gold layer, preserving the surface integrity. |

Work With Us

At Alternate Finishing, Inc., we serve customers across the USA and Canada in various industries with precious metal plating services including gold-plated nickel services. We have a quick turnaround and some jobs are done on the same day. We also always deliver as promised and we now want to help you get your nickel and gold plating needs met. Call us for a quote.