A reliable and well-rounded plating service provider should assess your needs, recommend suitable finishes, and adhere to industry standards.

There are so many plating methods, each with its unique strengths and weaknesses. This has led to the growth of the plating services business. However, it can be a challenge to find the right solution and a reliable service provider.

Plating Solutions For Your Business

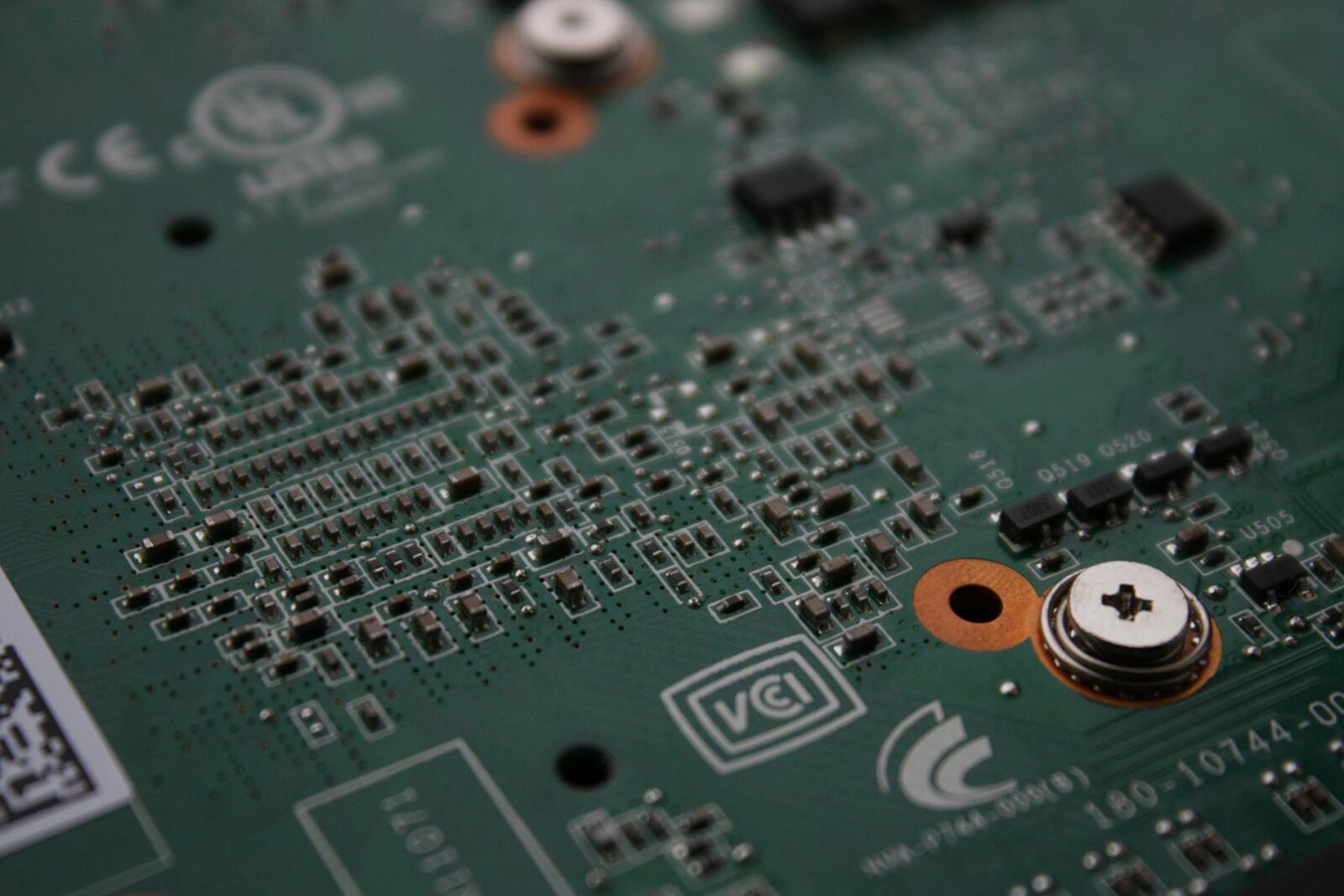

Plating is a surface finishing process in which a thin layer of metal or other materials is deposited onto a substrate. This is typically done to boost the properties of the base material and it is widely used in the automotive, aerospace, medical devices, electronics, manufacturing, and other industries.

AFI offers some of the most effective precious metal plating services available. At the highest level, these services fall into two categories: Electroplating and Electroless.

Electroplating Services

These plating services are widely offered in the metal finishing business because this process improves the durability, corrosion resistance, and functionality of metal components. The common electroplated materials are gold, silver, nickel, and copper and each is chosen based on the benefits it offers. For example, gold electroplating is chosen for electronics that require superior conductivity while nickel plating is considered when wear resistance is needed in mechanical parts.

Adhering to strict industry standards like MIL-SPEC, professional electroplating services optimize performance and extend the lifespan of critical electronic components.

Electroless Plating Services

This service is highly sought after for applications like coating complex geometries or precision components where even distribution is required. The aerospace, automotive, electronics, and other industries often use this method to achieve great corrosion resistance, wear protection, high conductivity, and overall reliability in their electronic components.

Nickel-based electroless plating is particularly popular because it offers high hardness and lubricity for mechanical applications. Therefore, fuel injection systems, medical implants, and other high-precision engineering parts widely use this method to achieve the reliability needed to function in their environments.

Metals Used in Precious Metal Plating Services

Metal plating offers a diverse range of finishes, each with unique properties and aesthetic qualities. The selection of the plating metal is crucial, as it directly impacts the final appearance, durability, and functionality of the coated object.

Copper Plating Services

Copper plating services are commonly used in manufacturing because of copper’s great conductive and adhesion properties. It is also resistant to corrosion. It serves as a base layer for other plating materials like nickel or gold. In electronics, copper plating boosts the properties of circuit boards and connectors for reliable electrical transmission.

The aerospace and automotive industries also use copper plating to reduce friction and wear on critical components.

For the medical and food processing applications, copper also has good antimicrobial properties that make it valuable in these industries.

Through expert-controlled plating processes, you can benefit from the adhesion strength, surface smoothness, and all other amazing benefits that copper plating has to offer.

Immersion Silver Plating Services

These precious metal plating services are especially valuable in the electronics industry since immersion silver plating is a cost-effective way of providing a highly conductive surface finish. If you need excellent solderability for PCBs and electrical contacts, this is one of the best choices.

Other Reasons to Choose Immersion Silver Plating

- Improves signal integrity, ensuring low contact resistance while protecting against oxidation.

- Eliminates the need for lead-based alternatives.

- A reliably corrosion-resistant coating.

Because of its properties, the automotive, aerospace, telecommunications, medical device manufacturing, and so many other industries benefit from this plating process, and with the right services, it can offer stable performance under extreme conditions.

Nickel Plating Services

This service is offered in instances where the strength of metal components against harsh environments is needed. When used, the resulting components are wear resistant and have strong protection against corrosion which makes this process applicable in several industries from electronics to aerospace.

The process can be applied through electroplating or electroless methods and each has distinct benefits. The electroplated nickel provides a bright finish, for instance, which can be used in decorative applications like automotive trims, while the electroless method is most often focused on functional aspects. Learn more about nickel plating services.

Gold Plating Services

This process creates a non-reactive and highly conductive surface when used. This is why gold plating services are commonly used in electrical connectors and circuit boards. Its high resistance to oxidation and tarnishing also makes it widely used in high-reliability applications like medical devices, telecommunications equipment, and military hardware.

The precious metal plating services offered here can be the hard gold or soft gold plating options. Hard gold is often alloyed with cobalt or nickel to increase wear resistance for high-contact components while the soft gold plating option, with higher purity, is used in cases of sensitive electronic applications that require superior conductivity.

Selecting a Reliable Plating Services Provider

If you need reliable and high-quality finishes, selecting the right precious metal plating services provider is important. Here are some important factors you must consider.

- Quality Assurance and Turnaround Time: A plating provider must consistently meet client specifications without delays. For instance, at Alternate Finishing, Inc., we guarantee reliability and deliver as promised. Some of our jobs are even completed and shipped within one day.

- Experience and Industry Expertise: Experience matters in metal finishing. Therefore, work with providers who have worked on several projects in mission-critical applications across various industries and have showcased their expertise in delivering consistent results in their plating services.

- Certifications and Compliance: A trustworthy plating company should hold industry-recognized certifications such as being an IPC member, being ITAR-registered, and holding various ISO certifications. These qualifications demonstrate a commitment to stringent quality control and the ability to handle even the toughest projects.

Work With Us

At Alternate Finishing, Inc. (AFI), we provide precious metal plating services to customers across the USA and Canada. We not only deliver high-quality finishes but also have the experience and certifications to back our claims.

AFI is an IPC member, and AS9100D, ISO 9001:2015, and ITAR registered. Many of our metal plating services are finished within one day and for customers with urgent needs, we often complete their jobs on the same day.

If you are looking for a trusted precious metal plating services provider, contact us today to request a quote.