Metal Finishing for the Defense Industry

Components for the defense industry must perform reliably even when exposed to extreme temperatures, vibration, and corrosive environments. These are the very conditions that demand precision-engineered surface treatments.

This is why the ITAR registered metal finishing services we provide at AFI enhance conductivity, corrosion resistance, and mechanical durability, while meeting rigorous military and aerospace standards.

What is the Process for ITAR-Compliant Metal Finishing?

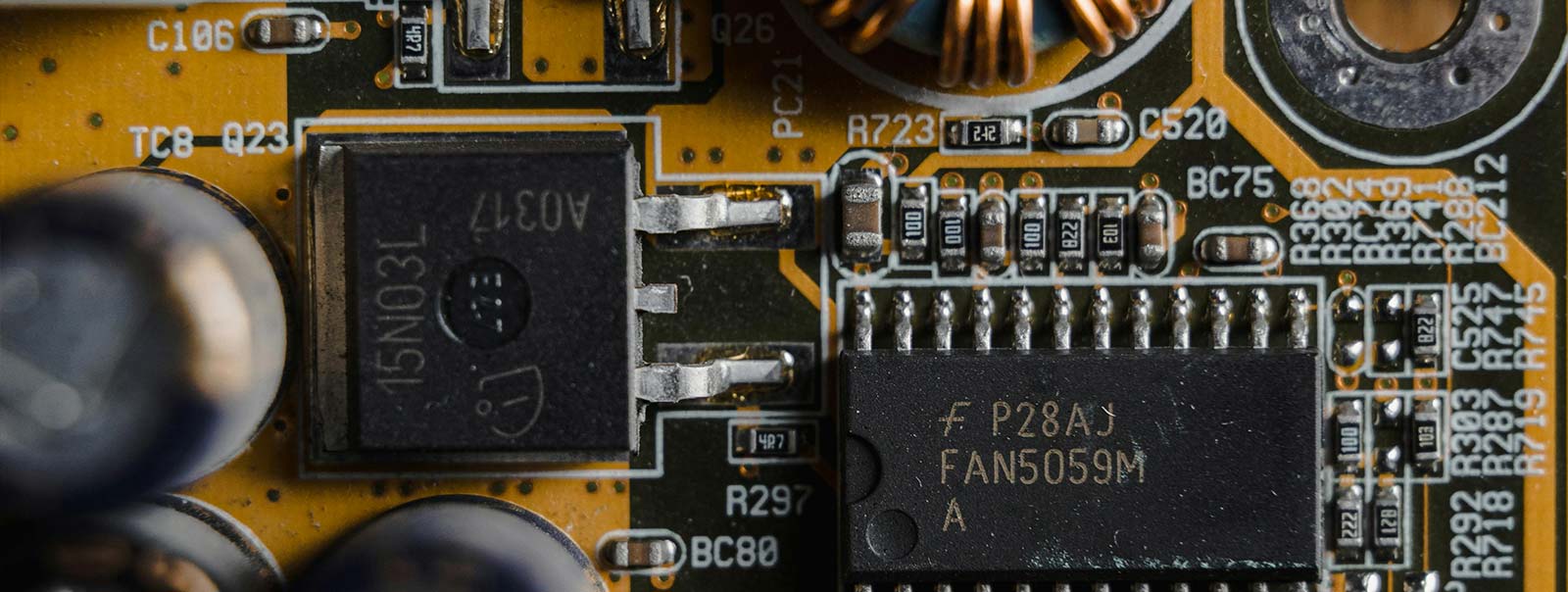

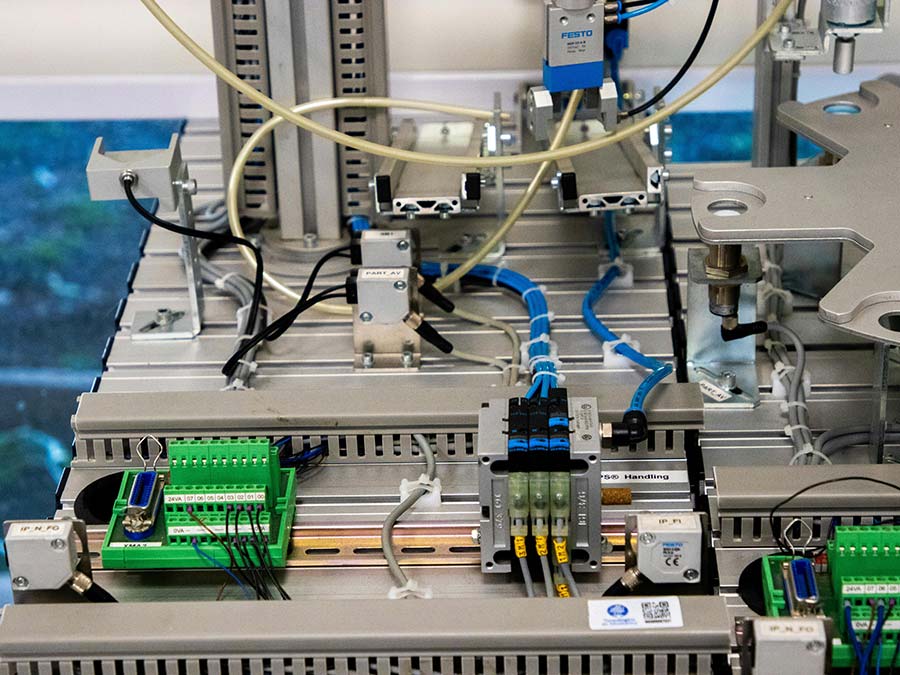

Our processes are designed to maintain dimensional integrity and surface uniformity, whether we’re plating high-reliability PCBs or metal housings. Because we’re ITAR-registered, customers can trust that all defense-related work is handled securely, and in full regulatory compliance.

Request a Quote

Our ITAR-Registered Metal Finishing Capabilities

Some of these include:

- Finishing for PCBs, connectors, housings, and other precision components.

- Gold, nickel, and copper plating with tight tolerance control.

- Full compliance with MIL-SPEC, IPC, and AS9100D quality standards.

- In-house processing within a secure, ITAR-compliant facility.

- Service coverage across the United States and Canada

What is Required for ITAR Compliance?

ITAR compliance requires that defense-related materials and services be registered, controlled, protected, and documented. ITAR registered metal finishing services, compliance isn’t just about keeping paperwork in order. It governs who can physically handle, access, or even discuss a defense-related component. That has real consequences in a finishing environment.

Metal finishing for the defense industry is strict in that, if even one technician doesn’t meet ITAR personnel requirements, the entire job becomes non-compliant.

Why ITAR Compliance Matters

This is where working with an ITAR-registered metal finishing provider makes a tangible difference. It ensures that your parts are processed by screened personnel, in a facility where access is restricted, documentation is controlled, and nothing leaves the shop floor without accountability.

More importantly, it helps protect your project from delays, fines, or rejections during final inspection because the requirements for ITAR registered metal finishing services aren’t just enforced on paper. They are enforced in practice, and defense contractors are expected to prove that every vendor in their chain took them seriously.

Work With Us

Some of our customers come to us after losing time and money with vendors who promised great results and never delivered. Others need a finishing shop that could actually meet the defense industry’s metal finishing compliance requirements without dragging the job out.

At Alternate Finishing, Inc., we’ve built our services around both of these realities.

If you want reliable metal finishes with quick turnaround times, we are here.

If you want to meet the ITAR requirements without mistakes or delays, we are your best option too. Call us for a quotе today.