At Alternate Finishing, Inc. (AFI), we provide precision nickel plating services that are designed to meet demanding performance and reliability standards. Our company offers two approaches to nickel plating: electrolytic and electroless nickel plating.

We cover both techniques at AFI because of the unique advantages that each method has, like a controlled, thicker coating for electrolytic plating and uniform coverage for electroless plating.

Both methods are used across industries to improve corrosion resistance, wear properties, electrical conductivity, and more to ensure that components can withstand harsh environments and perform reliably over time.

Learn more about each of the methods in our nickel plating services below.

Electroless Nickel Plating

The electroless process employs a chemical reduction technique wherein nickel ions in a solution are reduced and deposited onto a substrate without the need for an external power source.

This procedure offers great uniformity and coverage, even on complex geometries, which is ideal for so many applications.

Electrolytic Nickel Plating

In our electrolytic nickel plating services, we use an electric current to drive the deposition of nickel ions from a solution onto a substrate.

This method gives better control over the deposition rate and yields thicker coatings.

Work With Us

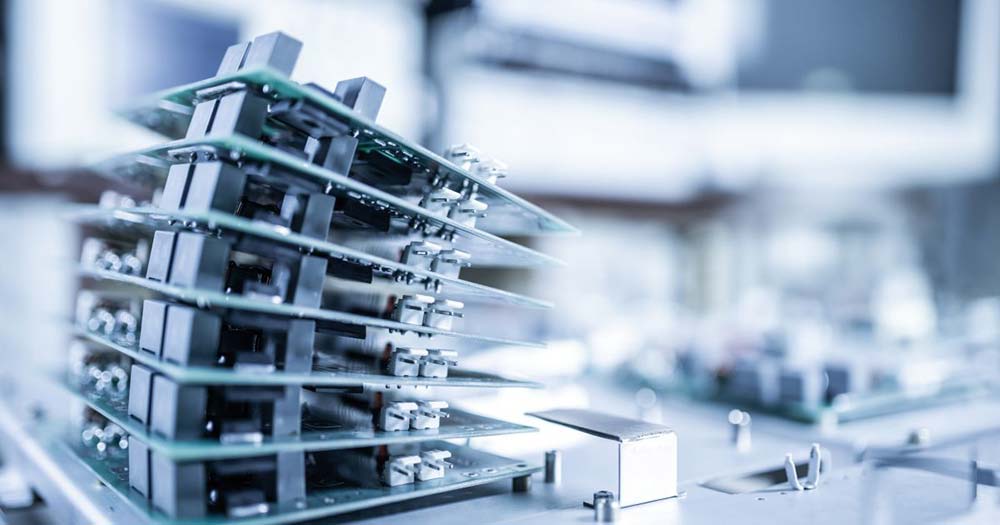

At Alternate Finishing, Inc., we serve customers across the USA and Canada with precious metal plating services, including electrolytic and electroless nickel plating services. We plate all types of printed circuits and many other parts. If you want your job done reliably and with quick turnarounds, call us for a quote.