How it Works

Our electroless nickel plating services begin with applying a uniform nickel layer to the part without using electricity. This coating then acts as a barrier that prevents diffusion between base metals like copper and the surface layers like gold.

This process is a chemical reduction reaction that deposits a layer of nickel evenly across the entire part’s surface. Since it doesn’t use electrical contact points, the electroless nickel plating deposition results in a consistent coating, even on irregular or recessed surfaces.

If you really need long-term reliability, even in challenging applications, then you might want to consider this method among your options.

Furthermore, for cases where you need full-surface protection or when the geometry of the component would make electrolytic methods unreliable, this process becomes an excellent choice.

Request a Quote

Some Applications of Electroless Nickel Plating

This method is a strong candidate when you need to:

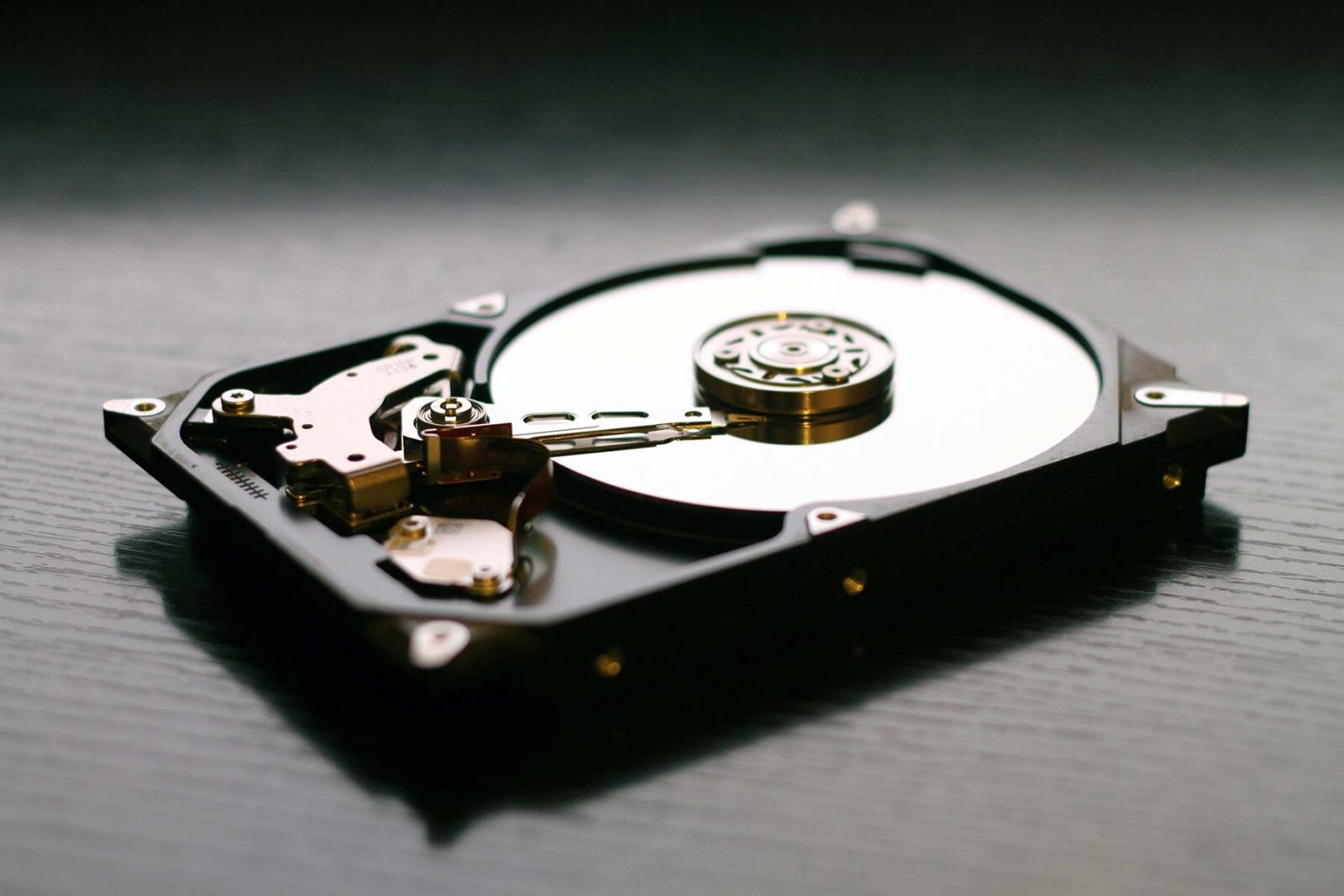

- Keep PCB traces protected from oxidation

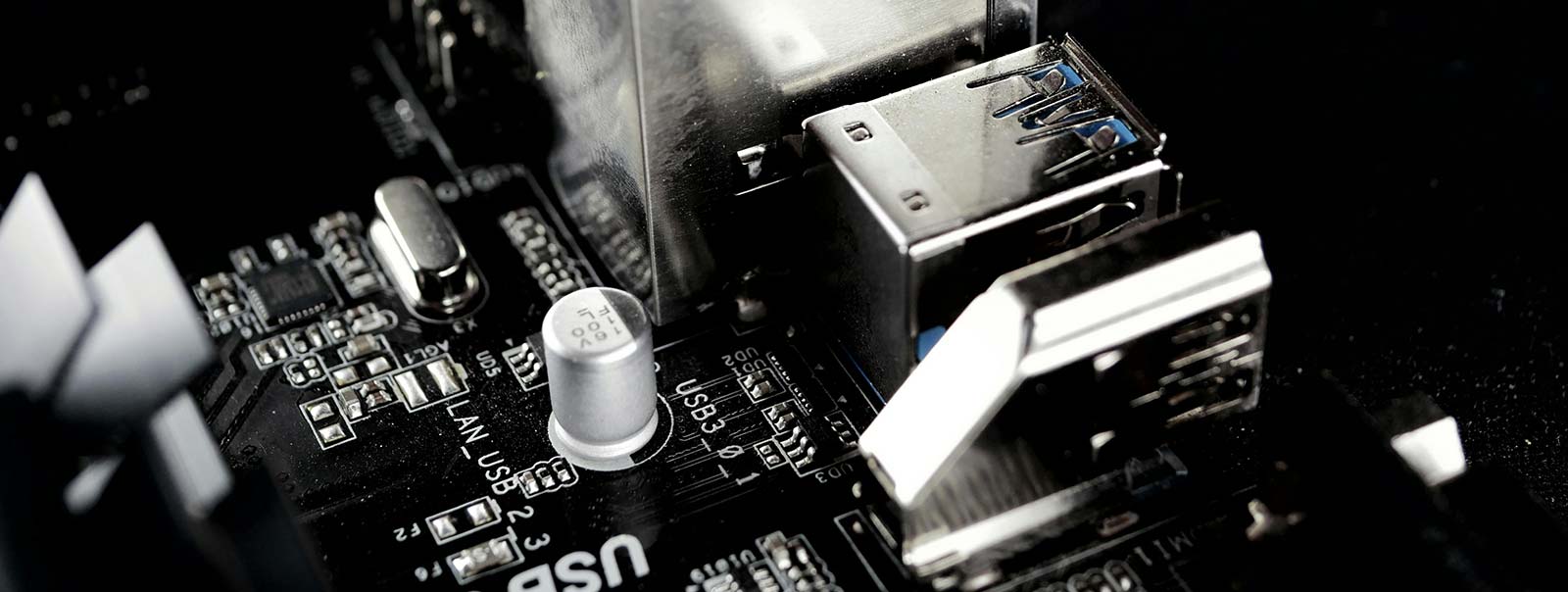

- Improve the contact surface of pins, pads, or connectors

- Shield enclosures or housings from wear or environmental exposure.

- Prevent electrical failures in high-reliability systems

- Add durability without deforming delicate parts.

We often use electroless nickel plating for the services we offer in aerospace, medical, and industrial electronics applications; basically, anywhere the cost of failure is too high to accept.

Important Considerations

No plating process is perfect for every project, though. Electroless nickel plating is no different. While it offers excellent uniformity and corrosion resistance, it also comes with trade-offs:

- It takes longer to deposit than electrolytic nickel plating

- The chemicals involved require close monitoring and careful maintenance

- Building up thick layers can extend your lead time

Let’s Talk About Your Plating Requirements

If you’re working on a tight timeline or need a plating partner you can count on, we’re here to help. At Alternate Finishing, Inc., we respond to quote requests the same day and often turn jobs around faster than expected, even on complex parts.

Even if you’re not sure whether electroless nickel plating is the best fit for your part or production goals, we’ll walk you through it. In many cases, we can even suggest ways to meet your functional requirements while keeping lead times and costs reasonable, since we have other finishes available.

Call us or request a quote today to see how our electroless nickel plating services can support your next project.