Electroless nickel plating is a process used by many industries to improve the durability of metal surfaces. This coating protects metals from corrosion, wear, and friction. The question many people may have is, “how does electroless nickel plating work?” If you’ve been curious about that, too you’re in the right place! This article will answer this question in detail.

Principles of Electroless Nickel Plating

Electroless nickel plating is a chemical deposition process that does not require an external electrical current, unlike traditional electroplating methods. Instead, it relies on an autocatalytic reaction to deposit a uniform layer of nickel onto a substrate. The electroless nickel plating process involves the reduction of nickel ions in a plating solution onto the surface of a catalytic substrate, typically a metal such as steel or copper, or a non-conductive material preheated with a conductive layer.

The plating solution consists of several key components. These include:

- Nickel Salts: The nickel ions we use for depositions come from nickel salts like nickel sulfate or nickel chloride. Nickel sulfate is the preferred option for acidic solutions, while nickel chloride works better in alkaline environments. These nickel compounds are foundational to how electroless nickel plating works, providing the necessary nickel ions to facilitate the deposition process.

- Reducing agents: Agents that aid in the reduction process are often sodium hypophosphite or formaldehyde. These help convert the nickel ions into solid metallic nickel.

- Complexing Agents: Complexing agents like citrate or EDTA (ethylenediaminetetraacetic acid) help stabilize the solution and control the rate of deposition during the electroless nickel plating process. These agents play a crucial role in keeping the solution stable and ensuring the desired deposition rate is maintained.

- pH Buffers: To maintain the optimal pH range for the plating reaction, typically around pH 4-5.

- Surfactants: Surfactants are chemicals that help spread the plating solution evenly across the surface. This ensures the solution covers the substrate uniformly. The surfactants aid in wetting and dispersing the plating solution, leading to a consistent coating.

Understanding how electroless plating works does begin with the appreciation of the components involved. But now, let us dive into the actual process.

Steps of the Electroless Nickel Plating Process

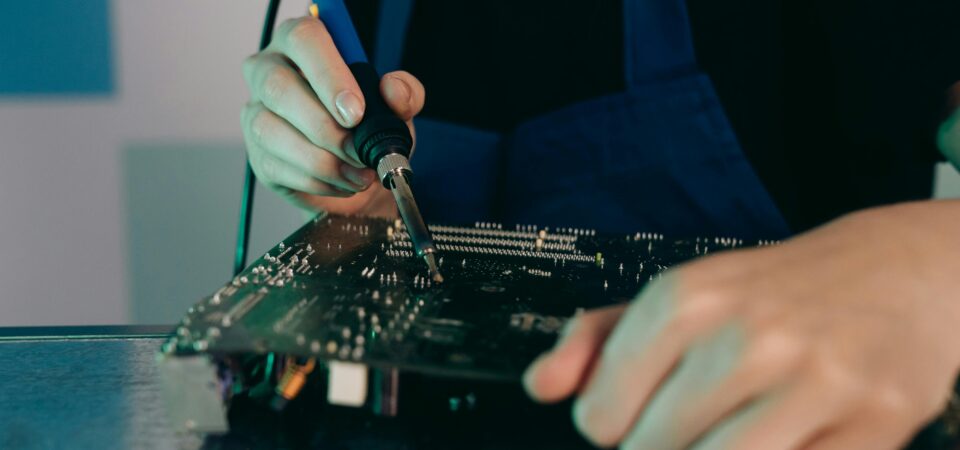

Surface Preparation: The substrate undergoes thorough cleaning and pretreatment to remove any contaminants, oxides, or surface impurities that could inhibit adhesion and plating uniformity. This may involve degreasing, alkaline cleaning, acid etching, and activation treatments.

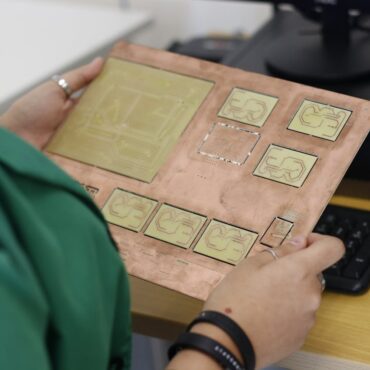

Activation: Sometimes, when working with non-conductive materials like plastics or ceramics, a special activation step is needed to make the surface conductive before depositing nickel. This can be done by sensitizing the surface with palladium chloride or using specialized activation solutions.

Immersion in Plating Solution: Immersion is likely the most visible step in how electroless nickel plating works. The substrate is placed in the nickel plating solution, where the catalytic surface helps the nickel deposit onto it. The solution is stirred to ensure even coverage, and more solution is added as needed to keep the chemical balance right.

Nickel Deposition: Nickel ions in the plating solution are reduced by the chemical reaction with the reducing agent, resulting in the deposition of a continuous, adherent layer of nickel onto the substrate surface. The rate of deposition is influenced by factors such as temperature, pH, concentration of nickel ions, and concentration of reducing agents.

Post-Plating Treatments: After the electroless nickel plating process, the substrate may undergo additional treatments to enhance its properties. These treatments can improve adhesion, corrosion resistance, or modify the surface characteristics. Some common post-plating treatments include heat treatment, passivation, sealing, or applying a topcoat. These processes help optimize the performance and longevity of the plated substrate.

How Alternate Finishing, Inc. Can Help You Achieve Reliable Plating Results

Understanding how electroless nickel plating works does not mean you now have the skills and tools required to get it done effectively. That’s where we come in.

At Alternate Finishing, Inc., we specialize in providing precious metal plating services to customers across the United States and Canada. One of the services we offer is electroless nickel plating.

Many of our jobs are finished and shipped within one day, and for customers with urgent needs, we can even get the plating jobs done on the same day. But this speed doesn’t come at the expense of reliability. As an IPC member, and AS9100D, ISO 9001:2015, and ITAR registered, we make sure that our work is reliable and meets the standards set by the industry. Therefore if you are looking for reliable electroless nickel plating experts to help you through the process, call us for a quote today.