These days, people want attractive, well-designed, durable, and high-quality devices. Thankfully, gold-plated electronics easily meet these goals because they blend functionality and visual appeal.

The Immersion Gold Plating Process

This is a specialized surface treatment used mainly in electronics. It enhances the conductivity, solderability, and corrosion resistance of materials like copper-based printed circuit boards (PCBs). Also known as electroless or chemical gold plating, this process deposits a thin layer of gold onto the substrate without using electricity. The gold coating improves the electrical and protective properties of the underlying material, making it more suitable for electronic components and circuits.

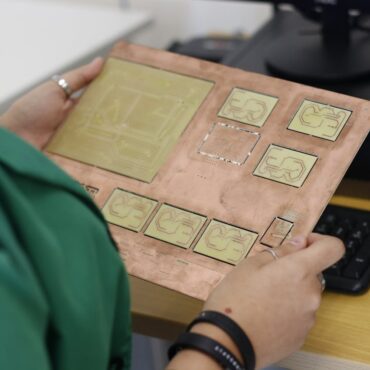

The plating process involves the following steps:

- Surface Preparation: The substrate is properly cleaned and prepared before plating. This removes any impurities, oxides, or organic materials from its surface so that the gold layer from the immersion gold plating process adheres properly and has a consistent appearance.

- Activation: The surface is then treated with a specialized solution containing a palladium-based catalyst. This catalyst serves to activate the substrate surface, facilitating the deposition of electroless nickel.

- Chemical Deposition: This is when gold-plated electronics get their gold on. The nickel-plated substrate is dipped into a solution containing gold ions, typically a gold chloride complex, and a reducing agent. The reducing agent triggers a chemical reaction that causes the gold ions to undergo reduction and deposit onto the nickel surface as metallic gold.

- Control and Monitoring: Throughout the deposition process, key parameters like solution temperature, pH, gold ion concentration, and exposure time are closely monitored and regulated. This ensures that the gold layer from the immersion gold plating process has the desired thickness and consistency across the entire substrate. Precise control is crucial to achieve reliable plating results.

- Post-Treatment: After the deposition step, the plated substrate may go through additional treatments. This could include rinsing to remove any leftover chemicals, drying to get rid of moisture, and inspecting the gold layer to check its quality.

Properties of an Immersion Gold-Plated Surface

- Conductivity: Gold is an outstanding conductor of electricity, which makes gold-plated substrates a fantastic choice for electronics and applications that need high electrical conductivity, like electronic circuits. The gold plating helps ensure efficient electrical flow, making it a preferred material for these types of applications.

- Solderability: The gold layer from the immersion gold plating process provides a dependable surface for soldering components onto the substrate. This ensures sturdy and long-lasting connections in electronic assemblies.

- Corrosion Resistance: Gold has excellent resistance to corrosion and oxidation. This means it can protect the underlying material from environmental factors like moisture and chemicals over the long term. Gold’s anti-corrosion properties help maintain the integrity of the surface it covers.

- Surface Flatness and Smoothness: Gold plating creates a uniform and smooth surface. This is advantageous for components with fine pitches and high-frequency applications, as surface irregularities can lead to significant distortion or impedance mismatches.

Applications of Immersion Gold Plating in Electronics

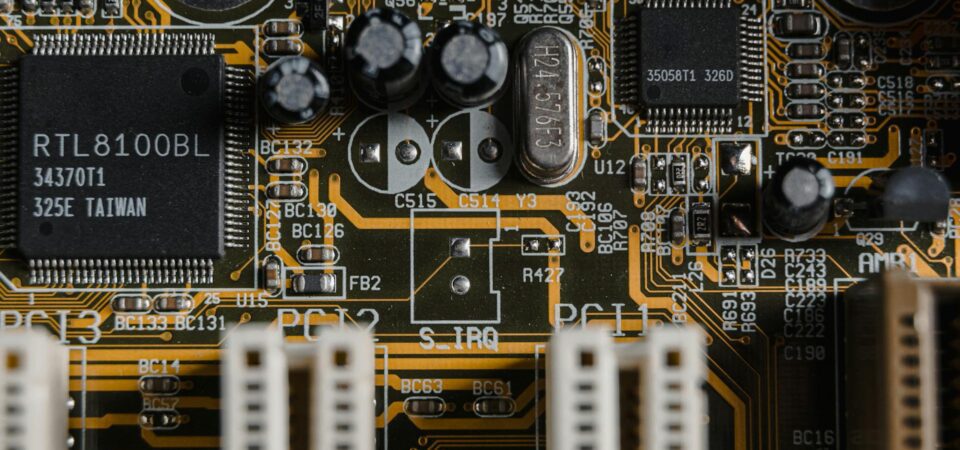

Printed Circuit Boards (PCBs)

The process creates a smooth, evenly distributed coating that improves the ability to solder and the electrical conductivity of PCBs. It also shields the exposed copper traces from oxidation. The thin layer of gold also acts as a barrier, protecting the circuitry from corrosion and preserving its integrity.

Wire Bonding

Semiconductor manufacturers often use immersion gold plating as a foundation for wire bonding. The gold layer has a smooth surface, allowing for precise positioning and bonding of delicate wires, which enables efficient connections between semiconductor chips and lead frames.

On top of that, gold’s excellent conductivity and resistance to oxidation ensure a reliable signal transmission, minimizing the risk of bond failure.

Connector Contacts

Connectors used in electronics often use immersion gold-plated contacts to ensure low contact resistance and reliable electrical connections. This gold layer also provides excellent wear resistance and corrosion protection which helps prolong the lifespan of the connectors while delivering and maintaining signal integrity over time.

The smooth surface of immersion gold makes it easy to insert and remove mating connectors. This helps reduce friction and prevent damage to the contact surfaces.

Immersion Gold Services at Alternate Finishing, Inc.

Elevate your electronic components to new heights of reliability and performance with our cutting-edge immersion gold plating technology. At Alternate Finishing, Inc., we pride ourselves in providing highly reliable gold plating services with quick turnarounds. If you are ready to have your gold plating solutions met, contact us to request a quote today.