Key Takeaways

- PCB metal finishing influences solder joint strength and stability

- Proper finishes prevent oxidation

- Hard gold extends connector life through consistent, low-resistance contact

- Controlled finishing processes ensure long-term PCB component reliability

Introduction: Why Surface Finish Matters

The metal finishing on PCBs looks really nice, but it’s not just cosmetic. It’s the decision that determines how long an assembly performs in the field.

A PCB might look great after reflow, but if pads oxidize or if the solder joints grow brittle intermetallics, the reliability of that PCB component will be compromised over time. This is why you need the right finish to set the stage for consistent solderability and stable, reliable connections.

Impact on Solder Joint Reliability

The quality of a solder joint depends heavily on the pad surface. In PCB metal finishing, finishes like ENIG provide excellent wetting because the thin gold layer keeps nickel pads free from oxidation during storage.

When solder spreads smoothly, the voids are minimized, but it also creates uniform joints that withstand thermal stress.

Another factor is the formation of intermetallic compounds (IMC). The strong and ductile joints need the right balance. If the IMC is too little, the bond will be weak; too much and the layer turns brittle.

Corrosion Prevention at Solder Joints

A controlled PCB metal finishing process stabilizes IMC formation through multiple thermal cycles. This helps assemblies pass the stringent reliability testing. Finally, good finishing also shields copper from corrosion at the solder interface, thereby keeping mechanical strength intact long after reflow.

Corrosion and Oxidation Control

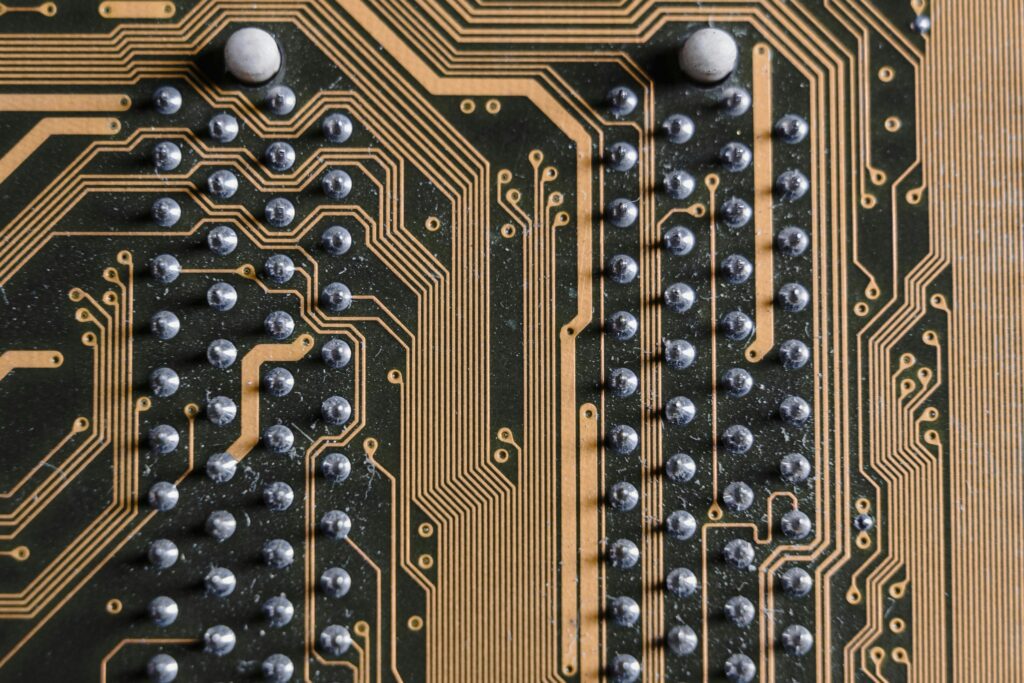

Humidity, air, and sulfur in the environment slowly attack exposed copper. PCB metal finishing prevents this by forming a barrier. ENIG is especially valued because its immersion gold maintains nickel’s stability over time.

By contrast, legacy options like HASL leave uneven surfaces prone to oxidation, which affects PCB component reliability.

Why This Matters

- Corrosion can cause everything from open circuits and shorts to poor solderability and component failure when boards sit on the shelf too long.

- For fine-pitch components where planarity is important, ENIG offers a flat surface that reduces solder bridging and boosts yields.

In short, the finish choice directly affects the PCB’s reliability and long-term consistency.

Wire Bonding Performance

When it comes to wire bonding, the surface finish greatly determines the connection strength. A PCB metal finishing option such as ENIG with reduction assisted immersion gold (RAIG) is often preferred because the resulting smooth, uniform surfaces and thicker gold allows bond wires to adhere consistently.

Oxidation on the Pad Surface

The thin layer of gold in ENIG prevents oxidation on the nickel below, keeping pads clean and receptive during assembly.

Oxidation is the enemy of a strong bond. Even a microscopic film on the pad can block the pressure weld between the wire and surface, leading to weak pull strength or early failure.

A stable PCB metal finishing ensures that the bond wires seat securely and maintain electrical continuity, which directly supports long-term PCB component reliability.

Contact Reliability (for Connectors)

Finishes like hard gold are the go-to choice in these areas because they’re tough enough to survive thousands of cycles without breaking down, and they keep resistance low so signals stay clean.

The difference shows up over time. A softer or thinner PCB metal finishing can start to pit or corrode due to porosity, especially in damp or dusty environments, and that tiny change is enough to cause unreliable connections.

Specifying the right thickness of hard gold isn’t just about durability. It’s what makes sure the board still performs the same way on the thousandth connection as it did on the first.

Mitigation of Reliability Issues

Choosing a finish is one step, but the consistency of the plating process makes the real difference.

At Alternate Finishing, Inc., we apply disciplined bath control and XRF thickness testing to ensure deposits meet spec every time. This level of quality control mitigates common issues like black pad or uneven nickel coverage.

Another thing is that there is confidence built when PCB metal finishing is tied to certifications like the AS9100D, ISO 9001:2015, and ITAR-registered credentials we have at Alternate Finishing, Inc.

Choosing the Right Finish for Long-Term PCB Component Reliability

No single finish is perfect for every board. Sometimes it will be ENIG for fine-pitch designs or harder gold finishes for connectors.

You can review our ENIG plating and defense-compliant ITAR-registered metal finishing. If you need reliable PCB metal finishing, request a quote.

Robert Peterson is President of Alternate Finishing, an AS9100D, ISO 9001:2015, and ITAR registered metal finishing provider serving customers across the USA and Canada. With more than four decades of experience in printed circuit boards and metal finishing, Robert is certified by the National Association of Metal Finishers as an electronic specialist. He’s also an avid photographer.